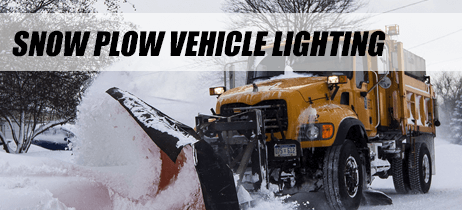

Snow Plow Vehicle LED Lights

Snow plow lights need to cut through snow glare, whiteouts, and heavy spray while staying reliable in salt and vibration. This page helps you build a complete snow plow warning package by shopping by product type below, so you can cover the front, sides, and rear without guesswork. Serving first responders and professionals since 2005.

Shop Snow Plow Lighting by Product Type

Use these categories to build a complete snow plow warning package.

Shop By HEAVY DUTY VEHICLE TYPE

What Each Category Is Best For

Full Size Light Bars: Maximum 360° visibility for municipal and fleet plow trucks.

Mini Light Bars: Lower profile roof coverage for pickups and contractors who still need strong output.

Interior / Exterior LED Light Bars: Flexible mounting for trucks with racks, visors, or exterior mounting constraints.

Grille and Surface Mount LED Lights: Tight, durable warning coverage on the front corners and push bumper zones.

Hideaway Strobe LED Lights: Clean OEM style installs in headlight/taillight housings when you want stealth when off.

LED Dash, Deck and Visor Lights: Fast interior warning for contractor trucks and removable seasonal setups.

Traffic Advisors: High clarity rear direction signaling when backing, closing lanes, or running a spreader.

Work and Scene Lighting: Task lighting for hook up, blade service, and night plowing in lots and drive lanes.

Wiring, Controls, and Mounting: The brackets, switch control, and connection hardware that makes the system reliable in salt and cold.

Snow Plow Best Sellers

Below you will find popular snow plow lighting options chosen for winter reliability, visibility, and easy integration with common plow truck layouts.

View Snow Plow Best Sellers | Need Help Choosing? Contact Support

Quick Setup Finder

Goal: Get noticed in whiteout conditions

Best Products: High output roof warning plus forward corner coverage

Best Mount Zones: Roofline, grille corners, front outer edges

Goal: Contractor pickup that removes after the season

Best Products: Magnetic or temporary roof warning plus an interior light

Best Mount Zones: Roof, dash/deck, rear window line

Goal: Municipal fleet standardization across multiple trucks

Best Products: Consistent roof warning, standardized rear signaling, unified controls

Best Mount Zones: Roof, rear upper zone, control center in cab

Goal: Strong rear warning for backing and spreading

Best Products: Rear directional signaling plus rear facing warning

Best Mount Zones: Rear upper window area, tailgate zone, headache rack/rear bar

Goal: Low profile while keeping full coverage

Best Products: Compact roof warning plus tightly mounted exterior warning points

Best Mount Zones: Roof low profile area, grille, side facing zones

| Mounting Style | Best For | Install Effort | Durability | Seasonal Flexibility |

|---|---|---|---|---|

| Magnetic Mount | Seasonal plow setups and quick removal | 1/5 | Moderate (depends on cleaning + cable routing) | High |

| Permanent Bolt Mount | Fleet installs and daily-duty plow routes | 4/5 | High | Low |

| Vacuum / Suction | Interior / short-duration temporary setups (weather dependent) | 1/5 | Low (cold-sensitive) | High |

| Vehicle-Specific Bracket Mount | Clean OEM look (grille/visor bracket installs) | 3/5 | High | Moderate |

Common Snow Plow Vehicles We See

- ¾ ton and 1-ton pickups with front plows (seasonal contractor setups)

- Municipal plow trucks with spreaders and dedicated upfit interiors

- Dump trucks and rack bodies running plows and material spreaders

- Fleet service trucks that plow lots at night and in low-visibility conditions

- Campus, HOA, and facilities trucks that need clean installs and simple controls

Technical Fitment & Installation Notes

- Keep warning lights clear of forward facing sensors and camera sight lines when equipped (placement matters more on newer trucks).

- Mounting height should account for snow spray lines and ice buildup so the light remains visible in active plowing.

- Route wiring away from plow hydraulics, articulation points, and sharp edges; add grommets and loom wherever the harness passes through metal.

- Seal connections like you expect salt exposure every day; corrosion control is a winter reliability requirement, not a nice to have.

- Plan synchronization and switching early so patterns stay consistent and the system is easy to operate with gloves.

- Confirm bracket clearance against plow lift frames (like the Boss SmartShield or Western UltraMount), push bumpers, and service access points so maintenance is not blocked mid season.

Compatible with Major Plow Brands

Many customers run our LED warning lights on trucks equipped with popular plow systems from Boss, Western, and SnowDogg. Clearance and placement depend on your truck, plow frame, and mounting zones, so confirm sight lines with the blade raised and fully angled before final mounting or drilling.

What Snow Plow Vehicles Need From Warning Lights

The operational environment

Snow plowing creates a visibility problem in every direction: reflective snow banks, glare, swirling snow dust, and heavy road spray. Plow trucks also operate at slow speed around traffic and pedestrians, which demands clear signaling, not just brightness. Cold starts and long shifts put extra pressure on electrical stability and operator simplicity.

The failure modes

The most common winter failures are corrosion at connectors, water intrusion at splices, loosened mounts from vibration, and wire chafing where the harness moves or rubs. Another frequent problem is “coverage gaps” where a plow frame, rack, or spreader blocks the most important viewing angles. If the lighting system is hard to control, operators stop using it correctly, which defeats the point.

Fitment zero drift note

Build the system around visibility zones first (front, side, rear), then choose product types that physically fit those zones without blocking critical vehicle functions.

Recommended Lighting Setups

Preset #1: Seasonal Contractor Pickup Package

Who it’s for: Contractors who need strong visibility but want a removable, seasonal setup.

Product types included: Removable roof warning, an interior warning light, and compact exterior points for the front corners.

Mounting zones: Roofline, dash/deck, grille corners.

Color guidance: Amber or amber/white is commonly selected for work vehicles. Verify local requirements.

Why it works: Fast install and removal while still providing high visibility coverage in typical contractor use.

Shop Mini Light Bars | View Snow Plow Best Sellers

Preset #2: Municipal Fleet 360° Standard

Who it’s for: Fleet managers standardizing multiple plow trucks for consistent operation and serviceability.

Product types included: Full roof warning plus rear directional signaling and unified controls.

Mounting zones: Roof, rear upper zone, centralized cab control.

Color guidance: Choose the fleet standard your agency uses. Verify local requirements.

Why it works: Repeatable layout across trucks reduces training time and makes maintenance predictable.

Shop Full Size Light Bars | View Snow Plow Best Sellers

Preset #3: Front Corner Visibility Priority

Who it’s for: Plow trucks that spend a lot of time in traffic turns, intersections, and tight lots.

Product types included: Compact front corner warning with strong side angle output plus supporting roof warning.

Mounting zones: Grille corners, bumper zones, roofline.

Color guidance: Match your local work vehicle standards. Verify local requirements.

Why it works: Improves the angles drivers actually see first, especially when the plow frame changes the truck’s silhouette.

Shop Grille and Surface Mount LED Lights | View Snow Plow Best Sellers

Preset #4: Rear Direction and Backing Control

Who it’s for: Trucks backing frequently, operating with spreaders, or doing lane protection.

Product types included: Rear directional signaling plus supplemental rear warning.

Mounting zones: Rear upper line, tailgate zone, rack or rear bar positions.

Color guidance: Use the rear signal colors your operation supports. Verify local requirements.

Why it works: Rear clarity reduces backing risk and makes your intent obvious to motorists approaching from behind.

Shop Traffic Advisors | View Snow Plow Best Sellers

Best Product Types for Snow Plow

Full Size Light Bars

Best for: Maximum 360° visibility on municipal and fleet plow trucks.

Tradeoffs: More permanent mounting and wiring planning.

What to check before buying: Mount footprint, control method, and clearance for racks and roof accessories.

Mini Light Bars

Best for: Contractor pickups needing strong visibility with a smaller footprint.

Tradeoffs: Less surface area than full size bars, so placement matters more.

What to check before buying: Mount type, cable routing plan, and seasonal removal process.

Interior / Exterior LED Light Bars

Best for: Flexible installs when roof mounting is limited or when you want non-roof coverage options.

Tradeoffs: Effectiveness depends on placement and line of sight.

What to check before buying: Mounting surface, viewing angles, and heat/clearance around install location.

Grille and Surface Mount LED Lights

Best for: Front corner warning, side angle visibility, and tight mounting zones.

Tradeoffs: Requires careful wiring protection against salt and spray.

What to check before buying: Bracket fit, cable exit protection, and beam spread for your mounting height.

Hideaway Strobe LED Lights

Best for: Clean installs that are hidden when off while still giving strong warning when activated.

Tradeoffs: Install complexity can be higher depending on the vehicle housings.

What to check before buying: Housing compatibility, ventilation/heat considerations, and sealing practices.

LED Dash, Deck and Visor Lights

Best for: Quick interior warning, seasonal setups, and supplemental front coverage.

Tradeoffs: Output and effectiveness depend on glass angle and tint.

What to check before buying: Mount position, glare control, and cable routing without pinching.

Traffic Advisors

Best for: Rear directional signaling when backing, lane guiding, or working in traffic.

Tradeoffs: Needs correct placement to be seen over tailgates and spreaders.

What to check before buying: Rear visibility line, pattern control, and intended viewing distance.

Work and Scene Lighting

Best for: Task lighting during night plowing, hook ups, and repairs.

Tradeoffs: Not a substitute for warning coverage.

What to check before buying: Beam shape, mounting angle, and whether it creates glare for the operator.

Wiring & Connectors

Best for: Building a reliable system that survives winter corrosion and vibration.

Tradeoffs: Cutting corners here causes most long term failures.

What to check before buying: Weather resistance, connector style, and proper strain relief.

Related: Wiring & Connectors

Switch Boxes and Control Panels

Best for: Simple operation, consistent patterns, and centralized control.

Tradeoffs: Requires planning so the layout matches driver workflow.

What to check before buying: Output capacity, switching method, and compatibility with your lighting plan.

Related: Control/Switch Boxes

Mounting Brackets

Best for: Correct fitment, reduced vibration issues, and clean, serviceable installs.

Tradeoffs: Wrong bracket choices can block access or reduce light effectiveness.

What to check before buying: Vehicle specific fit, corrosion resistance, and clearance.

Related: Mounting Brackets

Mounting and Installation

No drill vs permanent mounts

No drill options are great for seasonal work, but permanent mounts typically win for durability, stability, and clean wiring.

Wire routing safety

Use loom, grommets, and proper strain relief anywhere wire crosses metal, moves near articulation points, or runs near heat sources.

Power and compatibility (12V typical; verify amperage on product pages)

Most plow trucks are 12V, but total system draw depends on how many devices run at once and how you control them.

Control and synchronization

Plan how lights will be switched and whether you want synchronized patterns so the system looks consistent and professional.

Common install mistakes

- Routing cables where the plow frame or hood can pinch them

- Leaving connectors exposed to direct salt spray without sealing and strain relief

- Mounting too low where ice pack blocks output

- Creating glare into the cab or mirrors due to poor angle planning

- Mixing uncontrolled flash patterns that reduce clarity instead of improving it

Color and Flash Pattern Guidance

Amber and amber/white are common choices for work vehicle warning, but your allowed colors and pattern limits depend on where and how the vehicle is operated. Regulations vary; verify local and agency requirements. If you are comparing color specific options, start with Amber LED Strobe Lights and Amber and White LED Strobe Lights.

Compliance, Visibility, and Professional Standards

Avoid assuming certifications based on appearance or brightness alone, and see individual product listings for exact certifications/specs. Prioritize 360° coverage, clear separation of front/side/rear visibility zones, and mounting positions that stay visible above spray and snow buildup. This is a general guide, not legal advice. For broader shopping paths, start with LED Warning Lights and LED Strobe Lights, then confirm your state rules in the State Statutes Guide and review State Move Over Laws.

Why Choose Extreme Tactical Dynamics

Serving first responders and professionals since 2005. You get product type depth for snow plow lighting builds, plus practical help choosing mounts, controls, and wiring approaches that hold up in winter conditions. Warranty, shipping, and return details are shown on the site and on individual product listings so you can buy with confidence.

Frequently Asked Questions

Are snow plow warning light colors regulated?

Yes, but rules vary by state and agency. Confirm your local requirements before selecting colors and patterns.

What is the best way to build a complete snow plow warning package?

Start with coverage zones: front, side, and rear. Then choose product types that physically fit those zones without being blocked.

Do I need a snow plow light bar, or are strobes enough?

A light bar provides strong 360° awareness. Strobes add targeted coverage, especially at corners and the rear.

Where should I mount snow plow lights for the best visibility?

Use high, visible zones first, then fill corners. Avoid low mounts that get buried in spray or ice.

Will winter salt damage my lighting setup?

It can, if wiring and connections are not protected. Use sealed connections, loom, and proper strain relief.

How do I avoid glare and reflection off the hood and snow?

Aim and position lights to reduce direct reflection into the cab and mirrors. Balance output across zones instead of overloading one location.

Can I standardize one setup across a fleet of plow trucks?

Yes, and it helps training and maintenance. Standardize controls, flash behavior, and service parts across vehicles.

Are magnetic mounts safe for plowing?

They can be, if the surface is clean and cables are routed safely. Permanent mounts are usually more durable for daily duty trucks.

What matters most in a snow plow strobe light setup?

Placement and durability matter more than raw brightness. You want reliable output from multiple angles in harsh winter exposure.

How do I choose a rear warning solution for backing and spreading?

Prioritize clear rear visibility and directional signaling. Rear clarity reduces risk when working close to traffic and pedestrians.